Sep 8, 2020

This past spring, Virginia Commonwealth University broke ground on a new Science, Technology, Engineering and Math (STEM) building. When complete, the six-story, 168,000-square-foot facility will house lab, classroom, and office spaces for the University’s College of Humanities and Sciences.

To make room for construction of the STEM building, teams demolished an existing structure on the site known as the Franklin Street Gym. Included among its structural features was an inground swimming pool, which, after demolition, excavation, and foundation removal, resulted in an approximately 90-by-170-foot hole that needed to be filled in.

Filling in a hole of this size requires the purchase of several tons of material. And when combined with the significant margin of error often associated with volumetric calculations, the process may result in large amounts of wasted material and, ultimately, money. The project team at STEM decided to pursue a more sustainable alternative.

The demolition of the Franklin Street Gym resulted in over 5,000 tons of concrete and masonry material, typically destined for a landfill. However, anticipating the environmental impact of hauling away the debris, only to bring in new fill material, the project team saw an opportunity. They decided it would be better to reuse the material as an alternative fill method for the hole that the pool left behind. As the STEM facility is seeking LEED Silver certification, this was an additional opportunity to earn LEED credits. With approval from a geotechnical engineer, concrete was hauled from the site, crushed, and then returned to the site to begin the fill-in. While the entire process is completed in several phases over the course of four months, as of August 2020 the team has already used over 1,500 tons of crushed concrete.

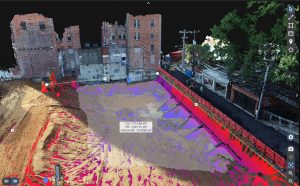

The efforts of the STEM team were documented to ensure accuracy, efficiency, and the positive environmental impact. A key part of this documentation process was the STRUCTR drones, which used aerial mapping technologies to generate 3D point clouds that served as an important cut/fill verification tool. These point clouds created a volumetric evaluation of the project’s earthwork. And the drones were able to estimate the amount of fill material needed within 30-cubic yards. The pre- and post-fill report provided by the volumetric calculations not only resulted in information that saved the project time and money, but it will also serve as a vital piece of documentation for LEED certification.

In addition to the documentation support, STRUCTR Advisors’ team is managing the sustainable building certification process for the project, aiming for LEED Silver and a goal of diverting over 75% of all construction and demolition waste from the landfill. To achieve credit for the use of the alternative fill method, the drone documentation, in conjunction with other supporting documents such as demolition hauling, alternative fill delivery receipts and site drawings, will narrate the complete lifecycle of the material and its positive impact.

The alternative fill method used by the project team at the VCU STEM building created a significant positive environmental impact. By thinking beyond typical strategies, over 1,500 tons of concrete were diverted from landfills and repurposed. A change from the normal discussion of cradle to grave product lifecycles, this case involved taking the material from cradle to cradle, giving it new use and life for another 50-100 years. With the help of STRUCTR Advisors’ consultants, the STEM team’s creative initiative was executed with a heightened level of precision and well-documented for future reference.