Apr 30, 2024

Stairwell Pressurization Design – Looking Past the Rule of Thumb – Part I, focused on the why’s and how’s. Why do we pressurize stairwells in the first place and how do we design them properly. Part II will go over several case studies that show successes and challenges with staircase pressurization. With regards to these challenges, we will discuss the design and construction pitfalls that created the breakdown and the means to overcome them.

Stairwell Supply Air

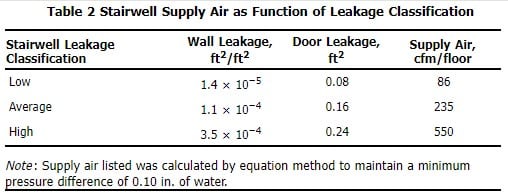

The primary factor regarding the amount of pressurization air needed is stairwell leakage. Table 2 below, lists the supply air needed to pressurize stairwells as a function of leakage classification. If the fan is oversized, the amount of supply air can be adjusted during commissioning to achieve successful pressurization. Because of the high cost of replacing undersized fans (including electrical wiring), rules of thumb chosen by designers usually incorporate an allowance for more leakage than anticipated.

Presenting the Challenge

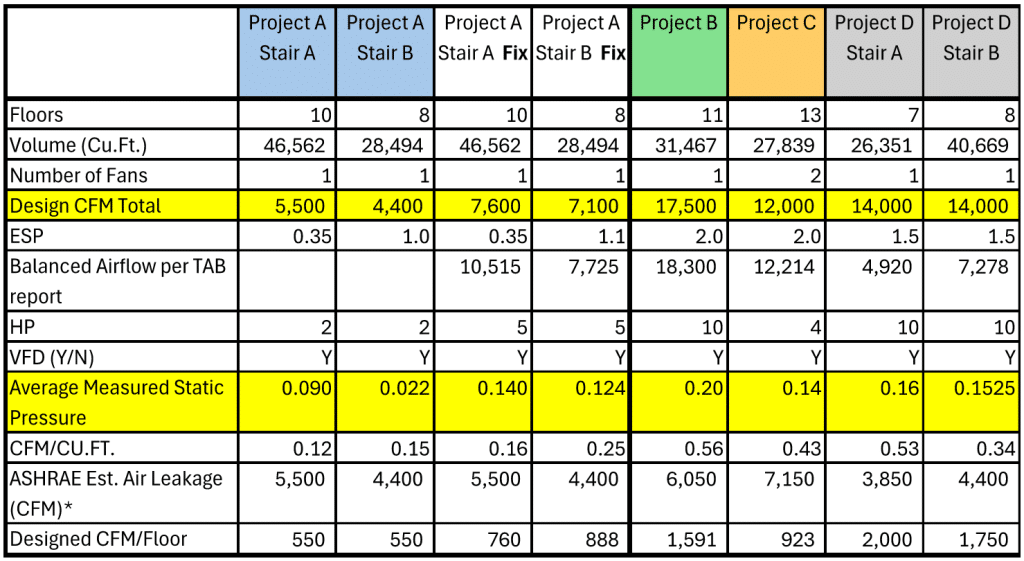

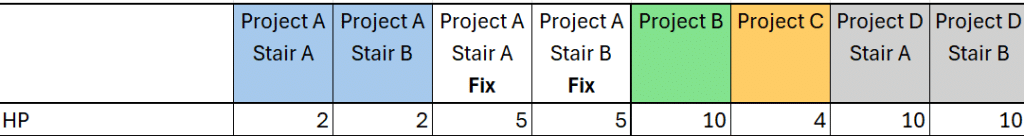

The table below shows four different projects (A, B, C, D) needing stairwell pressurization. Projects A, B, and D are not considered a simple stairwell design per ASHRAE. Only Project C can be considered a simple design because it is a standard 13-story hotel. Most hotels have very straightforward stairwells that are uniform throughout the whole structure.

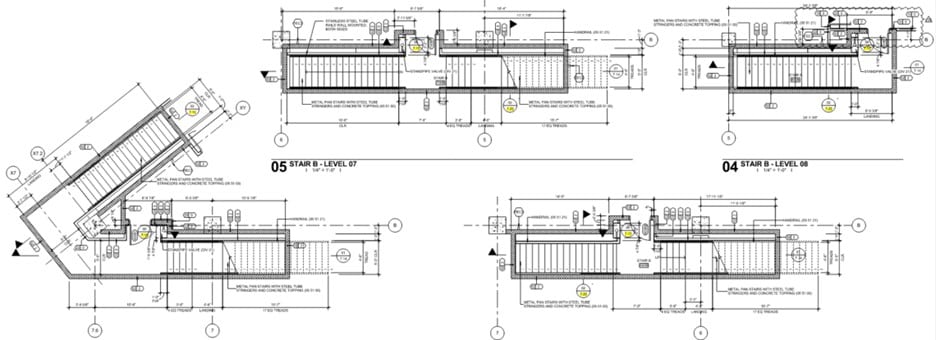

Project A is one project with two very different stairwells marked as Stair A and Stair B. Stair A has floors that are not uniform from floor to floor and is not considered a simple design. Stair B is just about the furthest from simple as a stairwell can get. None of the floors are uniform to another and they vary greatly in size, shape, and complexity from floor landing to floor landing.

In Project A, the engineer chose to utilize a single injection approach for both stairwells and located the fans on the roof. Stair A was directly injected from the roof to the top level of the stairwell. Stair B required a run of ductwork from the fan to the top level of the stairwell. For both stairwells in Project A, the engineer applied the simple approach and sized the fans based on 550 CFM per floor. Project B, the engineer chose to utilize a multiple injection approach with the pressurization fan located at the top level and the air ducted through a protected shaft.

Project C, the engineer chose to utilize the multiple injection with a multiple fan approach. Here the fans were placed at the lowest level and the highest level.

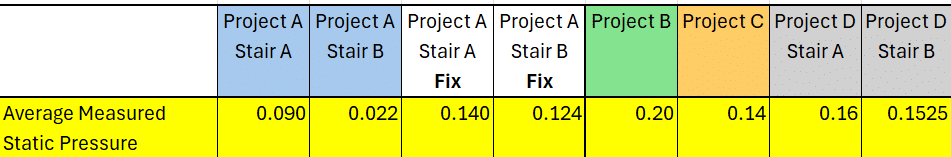

As you may note, the designed cubic feet per minute (CFM) airflow calculations are very different. The stairwell pressurization results varied widely as well. Each of the stairwells were tested under a code requirement to hold a minimum of 0.1″ of External Static Pressure (ESP) and a maximum of 0.35″ ESP. All fans were equipped with Variable Frequency Drives (VFD’s), a type of fan motor drive that controls the speed and force by varying the frequency of the incoming electricity.

Projects B, C, and D passed without any issues. Project A’s stairwells A and B did not pass and here is why:

To achieve the value of 0.09″ ESP at Stair A, the fan and VFD were driven far beyond the original design by maximizing the VFD to develop as much static pressure as the fan would allow, still coming up short. This is a case in point where just relying on rules of thumb can get you in trouble. Not only were Project A’s stairwells not simple in design, but they were also larger in volume per floor. The rule of thumb of maximum air leakage was applied and showed a negative result.

Correcting the Challenge

To bring the stairwells at Project A up to compliance (Project A, Fix), the contractor must walk every square inch of the stairwell and caulk any opening or perceived opening to ensure a tight seal at every level. Door sweeps were also added at each level. Once that effort was completed, the stairwell still did not meet the requirements on each floor. The next step was to increase the fan motor size and adjust the sheaves to the maximum availability for the fan and existing electrical conditions. As seen in the chart below, the increase in horsepower nearly doubled the fan’s output to bring the systems into compliance with the code requirements.

Understanding Stairwell Calculations

As stated in Part I of the blog, it is very important to look beyond the rules of thumb and provide adequate calculations and engineering to the scope. Understanding the stairwell’s layout is critical to successfully sizing the pressurization fans. In all the case studies above, even the simple hotel building, the sizing of the fans was much greater than the ASHRAE minimum recommendation on a CFM per floor basis. Not only do we need to understand the stairwell’s layout, but we also need to understand how each floor of the building is pressurized.

Projects B and D were complicated buildings that had different pressurization requirements on each floor. Some floors had lab spaces; others had typical office layouts. These are things that should be considered during the design phase to better prepare for the Certificate of Occupancy and tenant move in. Before the Certificate of Occupancy, all walls should be reviewed to meet the leakage requirements. When you get to this final testing, the door contractors, building automation contractors, and Testing Adjusting and Balancing (TAB) contractors should all be present to make sure all works as expected. Remember, when pressurizing a stairwell, the doors need to open with ease for proper evacuation. The short cut doesn’t get the job done faster. Always take the extra step in fully understanding the stairwells layout and how the building is pressurized. By doing so, the clients and its tenants can feel safe in case of emergency evacuations.