Construction and Embodied Carbon: Telling the Story of Emissions Tracking and Reporting

By: Sydney Covey

Feb 1, 2022

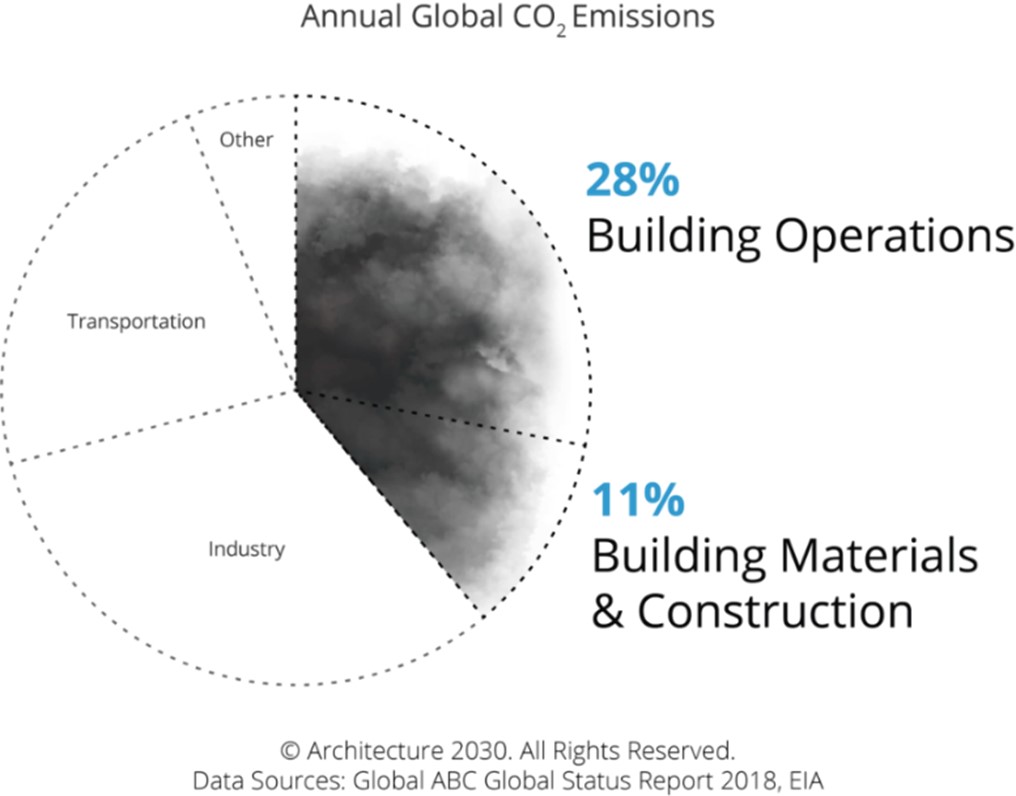

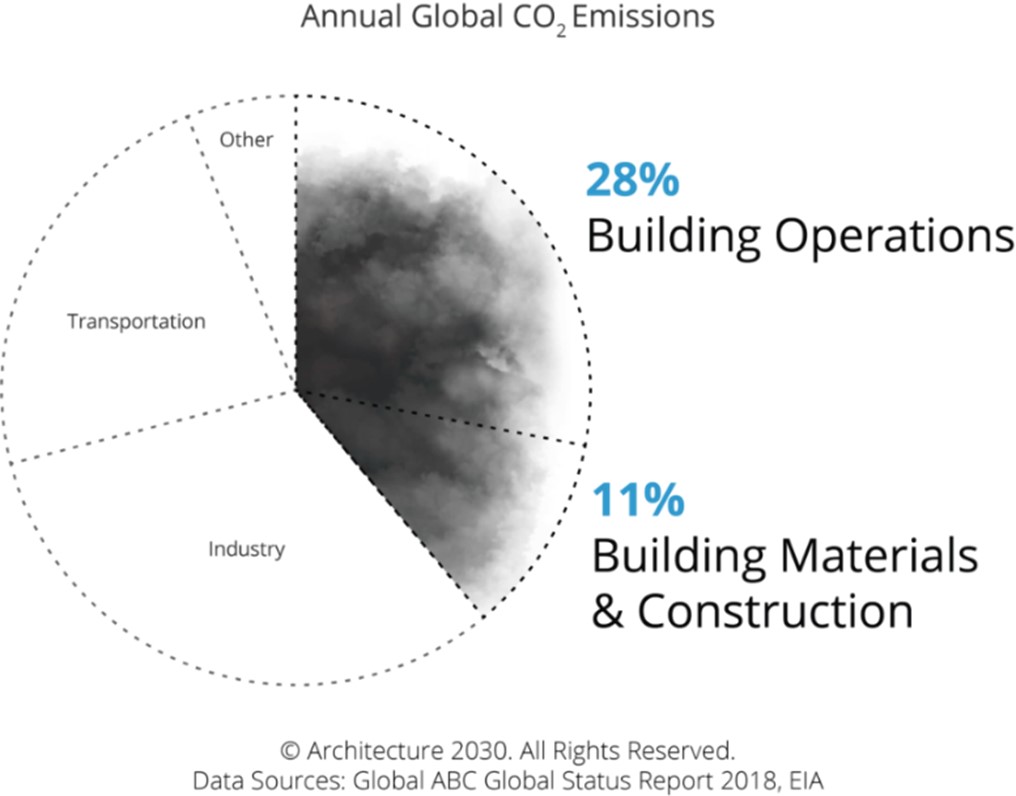

Figure 1: Annual global CO2 emissions by sector (courtesy of Architecture 2030)

The Importance of Carbon Tracking and Reporting

To meet climate targets of lowering the overall rise in global temperatures, eliminating greenhouse gas emissions from the built environment is essential. Buildings generate nearly 40% of annual global CO2 emissions. Building operations emissions account for 28% of annual carbon emissions, while building materials and construction (which is referred to as the embodied carbon of buildings) is responsible for 11% of the total annual emissions generated by the built environment (Architecture 2030).

Embodied Carbon of Buildings

One of the key strategies for reducing building sector emissions is targeting the reduction of embodied carbon. Embodied carbon is the carbon dioxide that is emitted throughout the production and manufacturing phases of a building’s lifecycle. From the extraction and manufacturing of raw materials to the actual construction process, tracking and reporting embodied carbon emissions has become one of the main ways to analyze a building’s impact on the environment. Construction industry leaders must set a standard when it comes to emissions reductions. This evolving standard includes the responsibility to track and report the built environment’s carbon emissions with the end goal of decarbonizing the built environment.

STRUCTR’s Process

Tracking and reporting on a project’s carbon impact requires cooperation from all trade partners within a project team to accurately represent the carbon emissions. Data must be collected from members that are involved in all stages of the project, from preconstruction for cost data to construction for waste management data.

Data collection means nothing without the actual ability to calculate and analyze it based on specific project needs. There are various tools that STRUCTR uses to assist with carbon analysis, with one of the main ones being the Environmental Protection Agency’s Waste Reduction Model (WARM). This model is a calculator used to track and report greenhouse gas emissions reductions, energy savings, and economic impacts from different waste management practices. WARM calculates and totals these impacts from baseline scenarios and alternative waste management practices – such as source reduction, recycling, anaerobic digestion, combustion, composting, and landfill.

For a previous client, STRUCTR utilized this tool to calculate the avoided emissions from the onsite processing of demolished concrete into reusable fill material at a jobsite. Raw data had to be collected from project team members on the amount of concrete demolished, the fuel usage of the trucks and equipment, and total equipment work hours. With the help of the WARM calculator, the avoided emissions from the alternative use of concrete were able to be found. This is just one example of how carbon tracking and reporting can help project teams understand their ability to mitigate their carbon emissions and incorporate sustainable alternatives into their construction practices.

The Future of Buildings Emissions: Reuse vs. Rebuild

The importance of carbon tracking, specifically embodied carbon tracking, presents the opportunity to reassess the importance of building reuse. It is estimated that 2/3 of the global building area that exists today will still exist in 2040, and the global building floor area is expected to double by 2060.

To achieve emission reduction goals, lifecycle choices for the existing building stocks are being called to adapt to the energy and resource efficient needs that can help lead to net zero. Operational carbon emissions can be reduced over time with the use of renewable energy options, but embodied carbon contributes to an alternative emissions route for existing buildings. This is because once the carbon is generated from the construction of the building, it cannot be reduced or avoided.

It is often incorrectly believed that to make a building more energy and resource efficient, it should be demolished and rebuilt with more efficient construction and operations techniques. But new construction will always contribute to embodied carbon, no matter how efficient the new building will operate. Another misleading assumption is that the emission reduction benefits gained by a newly constructed energy efficient building outweigh any of the negative environmental impacts caused by material extraction and construction, but this is not always the case.

A study conducted by the Carbon Leadership Forum at the University of Washington found that it takes 10 to 80 years (depending on the scale of the building and its function) for a new building that is 30% more efficient than an average-performing existing building to offset the negative impacts made through the construction process. The key to reducing emissions in the building sector is not to replace all existing structures with newly decarbonized buildings, but to utilize the existing building stock to adapt itself to the new age of decarbonization. Existing buildings can be remodeled without the need for extensive resource extraction and transportation, to then not only contain its existing carbon stock but also reduce (and hopefully one day eliminate) the total amount of emissions it creates.

The age of decarbonization that is approaching will lead to the tracking and reporting on embodied carbon to become an expectation of the building sector. By utilizing the technology of carbon tracking and reporting and adjusting the existing building stock to keep up with sustainable operation needs, the building sector will become an industry that contributes to emissions reductions goals. Check out STRUCTR’s previous blog, “Creating A More Sustainable Future with Decarbonization” to learn more about other ways carbon can be reduced.

Sources:

recent posts

Preventing Owner Risk in Contracts through Advocacy

Read More →

Safeguarding Property Value: The Role of Fit-Out Review in Facilities Management

Read More →

Facility Conditions Assessments Aid in Strategic Real Estate Decisions

Read More →

![]()

![]()