Sep 26, 2023

Stairwell pressurization in midrise buildings is a mechanical ventilation system. To pressurize stairwells, it is necessary to install fans to suck air into the stairwell while maintaining air pressure in adjoining areas. The increased attention to stairwell pressurization came to light when a recent client reached out for help in troubleshooting two stairwells that were not meeting the necessary air pressure during the functional performance test (FPT) by the commissioning agent, prior to the Certificate of Occupancy. Part one of this two-part series will focus on the whys and the design process of stairwell pressurization. Why do we pressurize stairwells in the first place and how do we design them properly?

Why Stairwell Pressurization is Important

No one wishes for a fire or smoke event within a building, but we certainly need to plan for them. During a smoke event, everyone needs to have a safe, fast, and low-stress way of exiting the building. In the event of an emergency, elevators are not always available, so taking the stairs is the next best thing. For mid- and high-rise buildings, the stairwells are to provide a smoke-free means of egress. Basically, once you enter the stairwell, you are in a safe place for the time it takes to navigate the stairs and exit the building. In lower-rise buildings (usually less than 75′ above fire truck access) it is assumed that people can exit the building faster than dangerous levels of smoke may fill the stairwells. In mid- and high-rise buildings, we need to protect these exits from entraining smoke for at least 20 minutes or 1.5 times the calculated evacuation time. To achieve this, the stairwell must be proven to provide between 0.10″ and 0.35″ of water pressure and a maximum door opening force of 30 pounds. Here is an excerpt from the International Fire Code to explain more:

909.20.5 Stairway and ramp pressurization alternative. (From the International Fire Code, IFC)

“Where the building is equipped throughout with an automatic sprinkler system in accordance with Section 903.3.1.1, the vestibule is not required, provided that each interior exit stairway or ramp is pressurized to not less than 0.10 inch of water (25 Pa) and not more than 0.35 inches of water (87 Pa) in the shaft relative to the building measured with all interior exit stairway and ramp doors closed under maximum anticipated conditions of stack effect and wind effect.”

Designing the right Stairwell Pressurization for your next Building

An engineer’s first look into understanding the design and layout of a stair pressurization system will be ASHRAE, the American Society of Heating, Refrigeration and Air Conditioning Engineers. There they will stumble across the ASHRAE Handbook and Chapter 54, Fire and Smoke. This is a great start but needs to not be the only step.

In most jurisdictions, the code requirement for the stairwell is to hold a minimum of 0.1″ of External Static Pressure (ESP) and a maximum of 0.35″ ESP, positive in relation to the occupied part of the building. This is at every doorway, on every floor. This becomes the start of the design process. The goal is to design a system that will positively pressurize the stairwell to a minimum of 0.1″ of ESP but a maximum of 0.35″ for doors to easily be opened but also be able to shut on their own during a smoke event.

ASHRAE states, “Some designers size fans for pressurized stairwells using their own rules of thumb, which are generally in the range of 300 to 550 cfm per floor. Such estimates can be appropriate for simple buildings such as those discussed previously.” There is a very important note in here that some may not pay close attention to if they are in a rush and don’t have much experience with these systems. Simple buildings. Not many buildings are truly considered “simple” these days. A simple building requires all floors to be very uniform in space, shape, and pressurization and the stairwells should be the same.

The difference between a simple building and a complex building is easy to see with a couple of example sketches. In typical hotels (think box hotels at every freeway exit), the stairwells are very uniform, construction materials are consistent, same area and elevation floor to floor. Complex stairwells can vary in height, volume, and even direction of flow. Some may have exterior fenestration and interior and will be constructed of different materials.

An example of a simple stairwell.

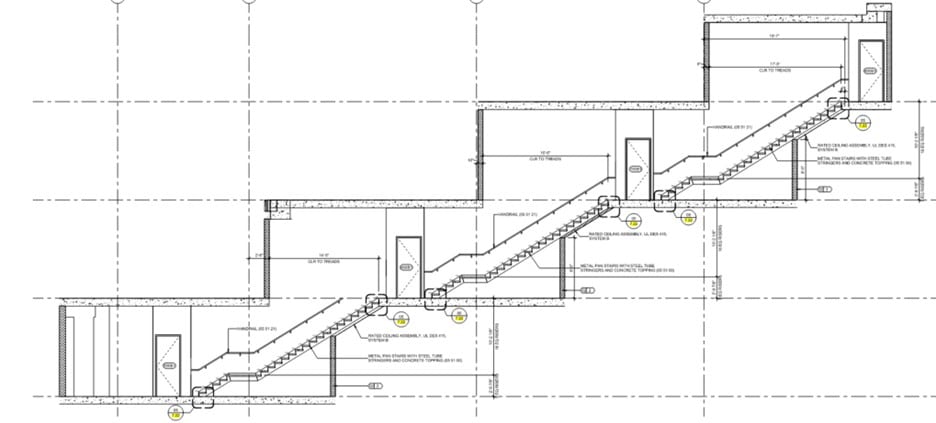

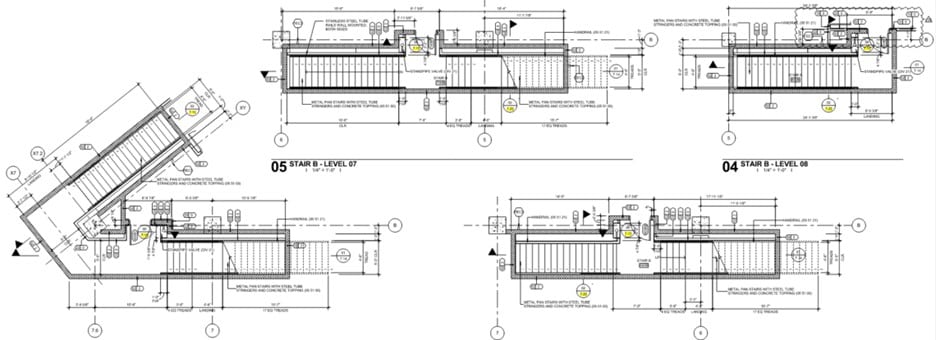

The diagrams below are examples of difficult stairwells that show levels of uniformity from floor to floor. They have large volumes and floors above that change direction to match the building’s characteristics and are not uniform in size or shape from floor to floor.

Air Distribution

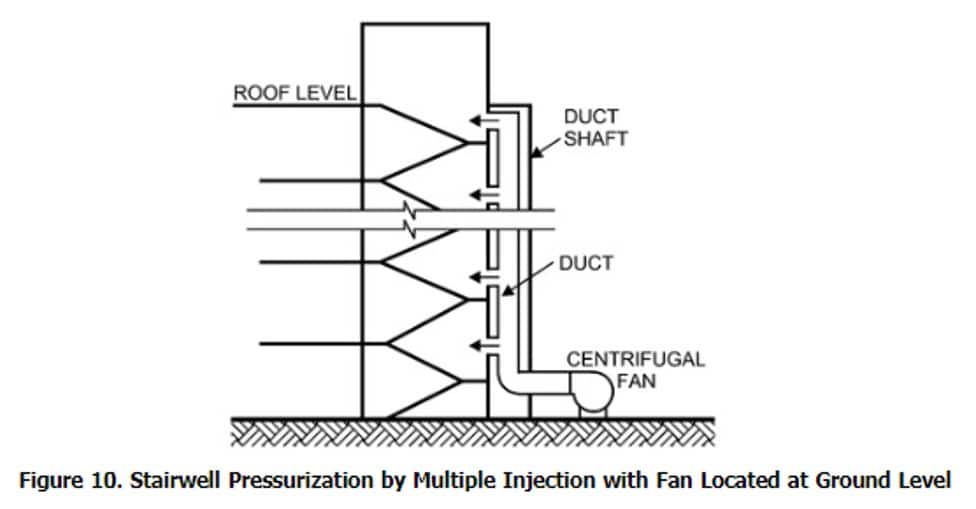

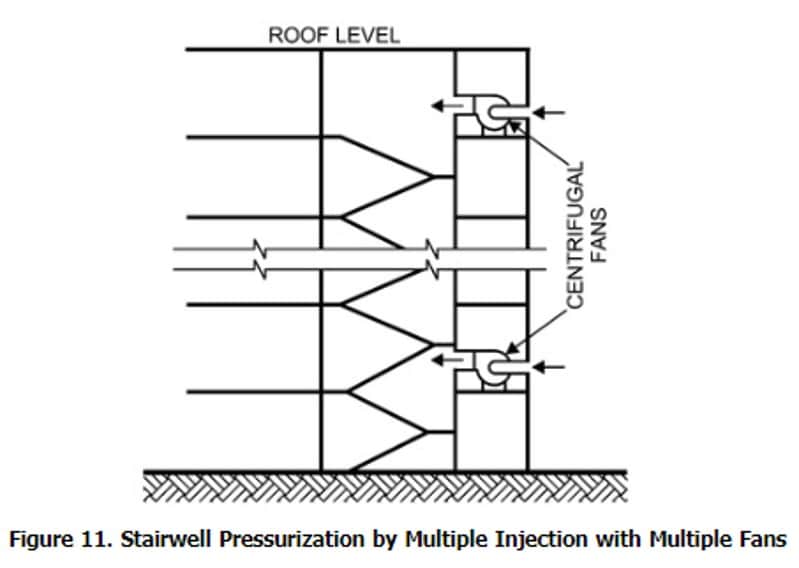

How does the air get distributed so that it can evenly pressurize the stairwell while maintaining the building relationships discussed previously? Here it is narrowed down to four basic layouts:

Once one of these layouts is chosen and proper calculations have been executed, the fans can be properly sized.

Diagrams from ASHRAE Handbook Chapter 54.

Don’t Ignore the Rule of Thumb:

Stairwell pressurization is often something that is overlooked during the construction process. It is an important life-saving system that each building should have.

Part two of this blog post will dig deeper into several case studies to show successes and failures in design and implementation. Regarding the failures, we will discuss the design and construction pitfalls that created them and the means to overcome them. It will also discuss the testing procedures and requirements to be sure your stairwell gets approval by your commissioning agent and code inspector.