Jun 30, 2023

In today’s world, the capabilities of technology are creating a huge impact in all industries. High-risk jobs are becoming safer, responsibilities are being completed more efficiently, and cost savings are increasing. The A/E/C industry is seeing this change with the use of drones. More specifically, drones are being used for remote inspections eliminating manpower and saving time for the general contractor and the client. Using drones for remote job site inspections can be done with limited personnel on-site. It can capture accurate data in hard-to-get locations with high-quality output. The user can also live stream and record an inspection for the client to review and keep on file. Drones are being produced with new technology at a rapid pace, and when it comes to using them for inspections, they are helping the Construction Manager (CM) stay on budget, schedule, and creating a safer job site.

Manual Inspections VS. Remote Inspections

Before drones, when inspections were needed on the job site, whether it was a two-story office building or an eight-story hospital, scaffolding or site equipment would be required for an inspector to perform a manual façade inspection. Building scaffolding is incredibly expensive and time consuming. It often takes a full day for construction scaffolding to go up and another day for it to be taken down. Equipment rental costs are also expensive and can be difficult to schedule on-site. This significant downtime and added expense can mean potential loss of revenue for the client. Using a drone for an inspection can drastically reduce the time an inspector has to be on-site and reduce their exposure to dangerous situations.

A drone site inspection.

On a recent multi-story project, a few exterior panels became loose on the building from above the third floor. The brackets supporting the panels were damaged and needed to be assessed. Within a couple of hours, a drone team was on-site and performing the inspection of the remaining brackets on the building’s exterior to better understand what caused the event. Drones were the perfect answer for getting at high and hard to reach places quickly and effectively. There was no need for additional equipment, personnel, or support to perform the inspection. Best of all, it was performed within hours of the original event. The photos were investigated by the inspector and decisions were made on safely adjusting and securing both existing and replacement panels. Completed expeditiously and without putting anyone in danger.

Outside of reacting to incident investigations, drones can be used proactively to confirm accurate installations across a construction site. For a new construction project, drones can be used to perform exterior inspections of ongoing installations. Highly visible details like brick alignment or GFRC panels can be inspected to ensure top quality output. As the building’s skin comes to completion, drones can be implemented to double-check existing work. They can be flown up and down the façade to reach any height required by the building and then deliver detailed images. In just a few hours, the entire building can be captured at a high level of detail. Drones can safely fly within 10 feet of the building to visually inspect the angle of tilt of bricks and panels and any other exterior component. After landing, the drone photos can be quickly processed and assessed for any discrepancies. Plans can be made to address issues while work continues in the field. This allows any rework to happen concurrently and aligns with ongoing construction. Drone services to turnover of photos and creation of actionable plans can take less than 24 hours. It is fast, safe, and reliable for the CM and inspector.

Newer Technology

The transition to and increased demand for remote inspections on construction sites is further aided by new drone technology. Gathering aerial data from the whole site quickly and efficiently is already a presumed benefit of drone technology. Now, drone inspections are aiding in construction operations when combined with drone mapping, by providing higher-quality visual data that can be processed into 3D point clouds. These maps can then be used throughout the duration of the project to monitor progress, report data to the client, and monitor inventory and materials on site. More accurate photogrammetry techniques and stronger cameras provide increased-quality photos and maps for project documentation. These maps can be coordinated with project models to better understand the project’s change over time. Routine flying can help identify deviating changes and spot problems well ahead of time. Being able to integrate drone inspections with other facets of data collection and use on construction sites helps create meaningful records and provides the information to make accurate decisions. This may help prevent the CM from running over budget and schedule.

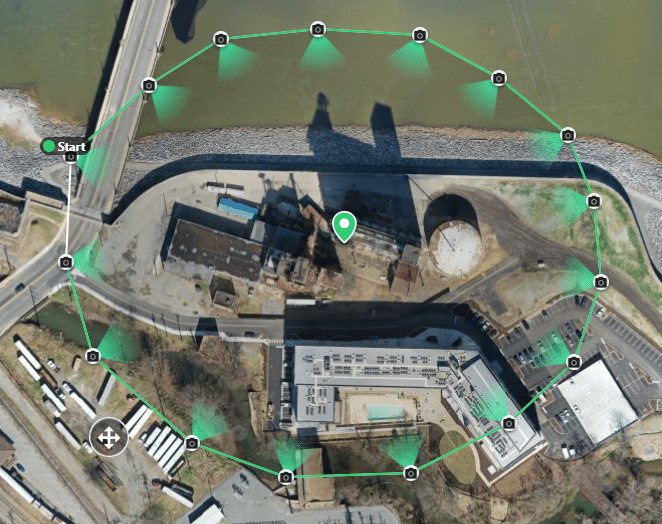

An example of site mapping and the path the drone takes to capture construction progress over time.

Let the Drone do the Work

Drone inspections are the first step of the inspection process. The second is physical resolution. It’s typical that drone inspections find little to be remedied. In fact, it is common for only a small percentage of building inspections to find a problem. When a problem is found, it will have to be addressed and reworked on-site by additional personnel. While rarer, this second step is a hefty cost. Having the drone pull all data needed to complete an inspection saves time on the front end, making the combined effort of costly rework more manageable. Drones help streamline many inspection processes without sacrificing data and value. Eliminating safety risks and increasing the speed of capture is a positive situation to be in.