Sep 13, 2022

Digital twins are gaining attention in the architecture, engineering, and construction (AEC) industry. A digital twin is simply a virtual representation of something in the physical world. In the AEC industry, a digital twin is a replica of a facility, site, or building’s infrastructure. Creating a virtual replica of a facility increases the likelihood of achieving your preferred outcome. Having a virtual replica leaves a memorable experience with the client, allows for enhanced collaboration and communication, and provides better construction management all from having these images of the project readily available. Building Information Modeling (BIM) often plays an important role in developing a digital twin by replicating the physical assets within a building, but many owners don’t have BIM models of older facilities. Without a BIM model, owners and facility managers can still leverage technology to gain insight into their buildings through a simulated digital twin that saves time and money for facility owners, managers, and stakeholders.

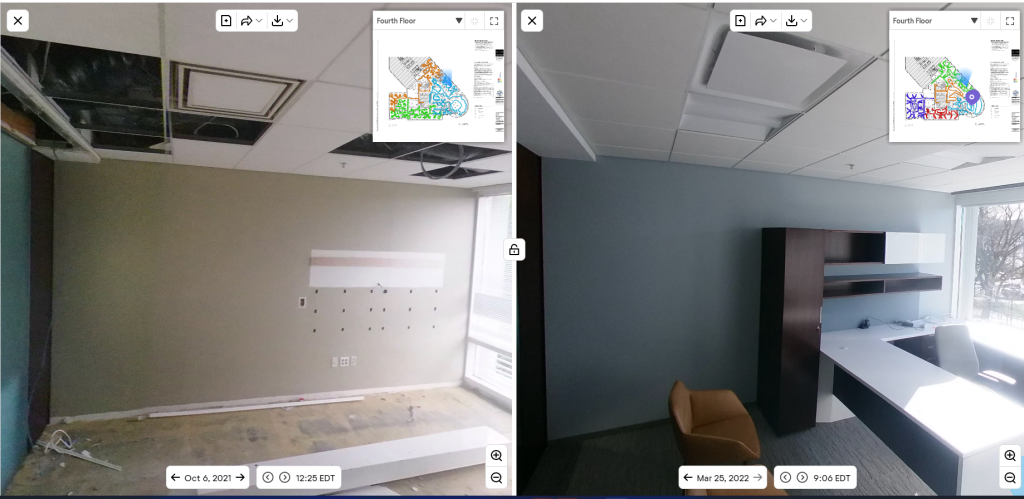

360° Images: The Google Street View Inside Your Digital Twin

Many construction teams are using reality capture technologies like 360° cameras to monitor progress and quality on job sites. These 360° images act like the Google Street view inside your digital twin, giving you the capability to capture images of everything that is being installed below floors, above ceilings, and behind walls. Once construction is complete, these images give the user an x-ray view, allowing facility owners to locate ducts, pipes, and equipment for future maintenance, repairs, and renovations. Capturing enough of these images throughout the building, you in essence have created a digital twin of the new facility.

If a BIM model does exist, images can be compared during construction. If you notice discrepancies between the two, then the model can be updated to match the photo, ensuring the owner receives an accurate as-built model that can be used effectively for facility management purposes after construction.

For existing facilities that are already constructed, the same 360° camera technology can be used to capture a comprehensive view of the existing conditions in and around the facility. Even if these cameras can’t see behind walls or ceilings, you can still capture valuable information about the space and the assets inside. Combining these images with aerial photos from a drone helps complete the digital twin of your property.

Whether it’s new construction or an existing facility, these high-resolution panoramic images are automatically aligned to a floor plan, locating each image relative to the building or site. Clicking on a picture allows an immersive view giving capabilities to pan and zoom in 360° degrees to inspect and quantify assets, much like the Google Street View of your facility. The photos can be shared and commented on with other stakeholders, which is perfect for virtual tours and remote inspections of a building or campus. During construction, this reduces the need for off-site stakeholders to travel to see progress, which increases their engagement in the project while also saving them time and money with less travel. Once the project is complete, owners and facility managers can use these photos to inspect their buildings remotely, which gives them quick access to accurate information while also limiting disruptions to the occupants in the building.

Laser Scanning: 3D Point Clouds as Digital Twins

When photos aren’t enough, consider using laser scanners to create a 3D model of the facility. Laser scanners quickly capture millions of 3D points, called a “point cloud”, that essentially becomes a type of 3D digital twin of the captured building or space.

For active construction projects, laser scanning can be used to verify installation and generate accurate as-built records for the project. If you have a BIM model, compare it to the point cloud to make sure everything is installed correctly. If there are discrepancies, use the point cloud to update the model and ensure the as-built BIM deliverables are accurate at the end of the job. Even if working without a BIM model, use laser scanning to document the as-built conditions in 3D, which adds significant value to the traditional 2D as-built drawings that are delivered for a new facility.

For existing buildings, laser scanning quickly captures precise, measurable 3D documentation of an existing space. Compared to traditional surveying and hand measurements, laser scanning is exponentially faster, more accurate, and more thorough. This provides accurate 3D measurements that can be used for maintenance activities and for coordination with any renovation or expansion project, eliminating the guesswork and avoiding unnecessary cost or schedule impacts for owners, designers, and contractors.

Success with Digital Twins

There’s a digital transformation happening in the industry and digital twins are unlocking their success and finding their rightful place in the hands of facility managers. The more that is put into the digital twin concept, the more benefits that will come out. With proper planning and thoughtful implementation, it’s easy to successfully apply these concepts on multiple projects, and empower facility managers with tools and information to save time and money.